|

Ningbo Permanent Magnet Materials Co.,Ltd

|

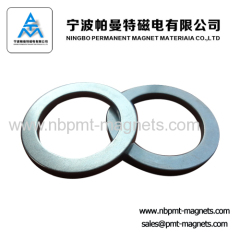

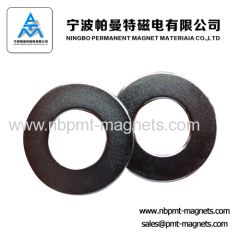

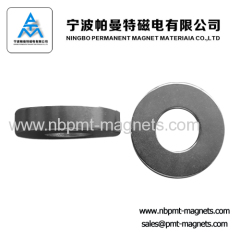

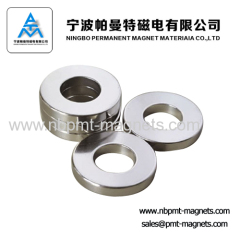

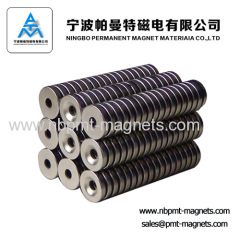

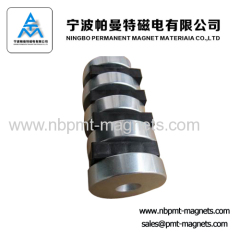

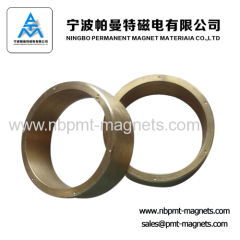

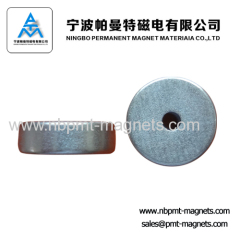

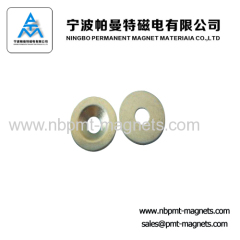

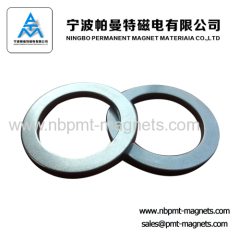

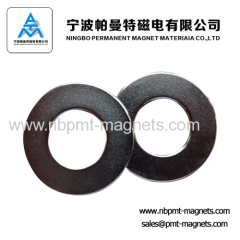

neodymium ring magnets for sale

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Rare Earth Neodymium Magnets Ring are with strong magnetic strength and can be used in high operating temperature. Offered at competitive prices.

product name n52 rare earth Neodymium Ring Magnets

feature

1.applied:industrialmagnets

2.shape:ring

3.Grade:N35-52,M,H,SH,UH,EH

5.size:Accordingto customer requirements

6.apply :motor Chuck, horn etc

7.material:Neodymium Magnets

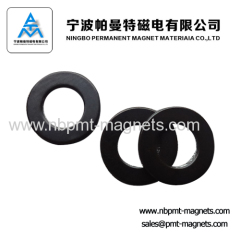

8.cladding material :Nickel, nickel and copper, nickel, zinc, gold, silver, andthe passivation, black epoxy resin

9.Max Working Temperature: 200℃

Specifications

1) High and stable Performance

2) Low Cost with less Dy or no Dy

3) Perfect Consistence

4) Low weight loss

magnet ring details:

1) Material: Sintered NdFeB Magnets

2) Grade:N35-52,M,H,SH,UH,EH

3) Shape: ring,block,disc,bar and so on

4) Size: according to customers' request

5) Coating: Ni, Zn, gold, copper, epoxy and so on

6) Application: sensors, motors, rotors, wind turbines,wind generators, loudspeakers, magnetic hooks, magnetic holder, filters automobiles and so on

Features Of NdFeB Magnet

Neodymium magnets are currently the most powerful magnets known to man. They have a strength which is around 10 times stronger than ceramic magnets. You can use a much smaller neodymium magnet in place of any other type and the holding force will be equal if not greater!!

Do not heat these magnets above 80 degrees C (175 F) or they will begin to lose there magnetic properties.

The curie temperature of these magnets is 310 degrees C - this is the point at which the magnets will totally lose their magnetic properties.

Neodymium magnets are also known as NdFeB or NIB magnets because of their chemical composition - Neodymium, Iron & Boron. They are also commonly referred to as Neodymium or Neo magnets.

-----High remanence (Br) and energy product (BHmax), the strongest type of permanent magnet

----- High coercivity (Hci), high resistance to demagnetization

------High mechanical strength,easily to be processed to many shapes

------Lower Curie Temperature,not suitable in high temperature but stable in ambient temperature

------Low anti-corrosion,need surface treatment