|

Ningbo Permanent Magnet Materials Co.,Ltd

|

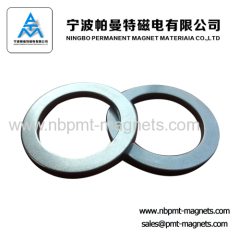

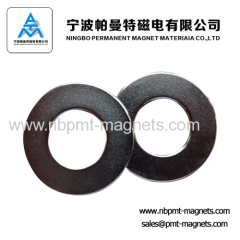

Neodymium Ring Magnets for motor and Chuck and horn

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Rare Earth Neodymium Magnets Ring are with strong magnetic strength and can be used in high operating temperature. Offered at competitive prices.

product name NiCuNi coating Neodymium Ring Magnets for motor and Chuck and horn

feature

1.applied:industrialmagnets

2.shape:ring

3.Grade:N35-52,M,H,SH,UH,EH

5.size:According to customer requirements

6.apply :motor

7.material :Neodymium Magnets

8.cladding material :Nickel, nickel and copper, nickel, zinc, gold, silver, andthe passivation, black epoxy resin

9.Max Working Temperature: 80 ℃

About Neodymium Magnets:

Neodymium magnets are one of rare earthpermanent magnets. Neodymium magnets are also known as NdFeB magnets, or neorare earth magnets. As its magnetic strength is very strong, people also simplycall it super strong magnets or super powerful magnets. The main elements ofthis magnet include neodymium (Nd), iron (Fe) and boron (B).

Magentic Properties

| Grade | Residual Induction | Coercive Force | Intrinsic Coercive Force | Maximum Energy Product | Maximum Working Temperature |

| Br | Hcb | Hcj | (BH)max | Tw | |

| mT | kA/m | kA/m | kJ/m3 | ||

| [kGs] | [kOe] | [kOe] | [MGOe] | ||

| N35 | 1170-1220 | ≥868 | ≥955 | 263-287 | 80° |

| [11.7-12.2] | [≥10.9] | [≥12] | [33-36] | ||

| N38 | 1220-1250 | ≥899 | ≥955 | 287-310 | 80° |

| [12.2-12.5] | [≥11.3] | [≥12] | [36-39] | ||

| N40 | 1250-1280 | ≥907 | ≥955 | 302-326 | 80° |

| [12.5-12.8] | [≥11.4] | [≥12] | [38-41] | ||

| N42 | 1280-1320 | ≥915 | ≥955 | 318-342 | 80° |

| [12.8-13.2] | [≥11.5] | [≥12] | [40-43] | ||

| N45 | 1320-1380 | ≥923 | ≥955 | 342-366 | 80° |

| [13.2-13.8] | [≥11.6] | [≥12] | [43-46] | ||

| N48 | 1380-1420 | ≥923 | ≥955 | 366-390 | 80° |

| [13.8-14.2] | [≥11.6] | [≥12] | [46-49] | ||

| N50 | 1400-1450 | ≥796 | ≥876 | 382-406 | 80° |

| [14.0-14.5] | [≥10.0] | [≥11] | [48-51] | ||

| N52 | 1430-1480 | ≥796 | ≥876 | 398-422 | 80° |

| [14.3-14.8] | [≥10.0] | [≥11] | [50-53] | ||

| 30M | 1080-1130 | ≥805 | ≥1114 | 223-247 | 100° |

| [10.8-11.3] | [≥10.1] | [≥14] | [28-31] | ||

| 33M | 1130-1170 | ≥836 | ≥1114 | 247-263 | 100° |

| [11.3-11.7] | [≥10.5] | [≥14] | [31-33] | ||

| 35M | 1170-1220 | ≥868 | ≥1114 | 263-287 | 100° |

| [11.7-12.2] | [≥10.9] | [≥14] | [33-36] | ||

| 38M | 1220-1250 | ≥899 | ≥1114 | 287-310 | 100° |

| [12.2-12.5] | [≥11.3] | [≥14] | [36-39] | ||

| 40M | 1250-1280 | ≥923 | ≥1114 | 302-326 | 100° |

| [12.5-12.8] | [≥11.6] | [≥14] | [38-41] | ||

| 42M | 1280-1320 | ≥955 | ≥1114 | 318-342 | 100° |

| [12.8-13.2] | [≥12.0] | [≥14] | [40-43] | ||

| 45M | 1320-1380 | ≥995 | ≥1114 | 342-366 | 100° |

| [13.2-13.8] | [≥12.5] | [≥14] | [43-46] | ||

| 48M | 1370-1430 | ≥1027 | ≥1114 | 366-390 | 100° |

| [13.7-14.3] | [≥12.9] | [≥14] | [46-49] | ||

| 50M | 1400-1450 | ≥1033 | ≥1114 | 382-406 | 100° |

| [14.0-14.5] | [≥13.0] | [≥14] | [48-51] | ||

| 35H | 1170-1220 | ≥868 | ≥1353 | 263-287 | 120° |

| [11.7-12.2] | [≥10.9] | [≥17] | [33-36] | ||

| 38H | 1220-1250 | ≥899 | ≥1353 | 287-310 | 120° |

| [12.2-12.5] | [≥11.3] | [≥17] | [36-39] | ||

| 40H | 1250-1280 | ≥923 | ≥1353 | 302-326 | 120° |

| [12.5-12.8] | [≥11.6] | [≥17] | [38-41] | ||

| 42H | 1280-1320 | ≥955 | ≥1353 | 318-342 | 120° |

| [12.8-13.2] | [≥12.0] | [≥17] | [40-43] | ||

| 45H | 1320-1360 | ≥963 | ≥1353 | 342-366 | 120° |

| [13.2-13.6] | [≥12.1] | [≥17] | [43-46] | ||

| 48H | 1370-1430 | ≥995 | ≥1353 | 366-390 | 120° |

| [13.7-14.3] | [≥12.5] | [≥17] | [46-49] | ||

| 35SH | 1170-1220 | ≥876 | ≥1592 | 263-287 | 150° |

| [11.7-12.2] | [≥11.0] | [≥20] | [33-36] | ||

| 38SH | 1220-1250 | ≥907 | ≥1592 | 287-310 | 150° |

| [12.2-12.5] | [≥11.4] | [≥20] | [36-39] | ||

| 40SH | 1250-1280 | ≥939 | ≥1592 | 302-326 | 150° |

| [12.5-12.8] | [≥11.8] | [≥20] | [38-41] | ||

| 42SH | 1280-1320 | ≥987 | ≥1592 | 318-342 | 150° |

| [12.8-13.2] | [≥12.4] | [≥20] | [40-43] | ||

| 45SH | 1320-1380 | ≥1003 | ≥1592 | 342-366 | 150° |

| [13.2-13.8] | [≥12.6] | [≥20] | [43-46] | ||

| 28UH | 1040-1080 | ≥764 | ≥1990 | 207-231 | 180° |

| [10.4-10.8] | [≥9.6] | [≥25] | [26-29] | ||

| 30UH | 1080-1130 | ≥812 | ≥1990 | 223-247 | 180° |

| [10.8-11.3] | [≥10.2] | [≥25] | [28-31] | ||

| 33UH | 1130-1170 | ≥852 | ≥1990 | 247-271 | 180° |

| [11.3-11.7] | [≥10.7] | [≥25] | [31-34] | ||

| 35UH | 1170-1220 | ≥860 | ≥1990 | 263-287 | 180° |

| [11.7-12.2] | [≥10.8] | [≥25] | [33-36] | ||

| 38UH | 1220-1250 | ≥876 | ≥1990 | 287-310 | 180° |

| [12.2-12.5] | [≥11.0] | [≥25] | [36-39] | ||

| 40UH | 1250-1280 | ≥899 | ≥1990 | 302-326 | 180° |

| [12.5-12.8] | [≥11.3] | [≥25] | [38-41] | ||

| 28EH | 1040-1080 | ≥780 | ≥2388 | 207-231 | 200° |

| [10.4-10.8] | [≥9.8] | [≥30] | [26-29] | ||

| 30EH | 1080-1130 | ≥812 | ≥2388 | 223-247 | 200° |

| [10.8-11.3] | [≥10.2] | [≥30] | [28-31] | ||

| 33EH | 1130-1170 | ≥876 | ≥2388 | 247-271 | 200° |

| [11.3-11.7] | [≥10.5] | [≥30] | [31-34] | ||

| 35EH | 1170-1220 | ≥876 | ≥2388 | 263-287 | 200° |

| [11.7-12.2] | [≥11.0] | [≥30] | [33-36] | ||

| 38EH | 1220-1250 | ≥899 | ≥2388 | 287-310 | 200° |

| [12.2-12.5] | [≥11.3] | [≥30] | [36-39] | ||

| 28AH | 1040-1080 | ≥787 | ≥2624 | 207-231 | 220° |

| [10.4-10.8] | [≥9.9] | [≥33] | [26-29] | ||

| 30AH | 1080-1130 | ≥819 | ≥2624 | 223-247 | 220° |

| [10.8-11.3] | [≥10.3] | [≥33] | [28-31] | ||

| 33AH | 1130-1170 | ≥843 | ≥2624 | 247-271 | 220° |

| [11.3-11.7] | [≥10.6] | [≥33] | [31-34] |